No products in the cart.

Noob Factory Rolex Replica

The Secret Of The Rolex Fake GMT-Master II Two-tone Bezel

Rolex relies on its professional knowledge to produce, in addition to black ceramic bezels, unique blue and green Cerachrom bezels for the Oyster Perpetual Submariner Date and 18ct gold Oyster Perpetual Yacht-Master II since 2007. In 2010, the brand further developed bezel technology and set an integrated Cerachrom bezel for the Cosmograph Daytona watch. Since then, its design has continued to evolve, from initially black to brown in 2013. This brown bezel model is made of platinum and was specially designed to celebrate the 50th anniversary of this legendary chronograph.

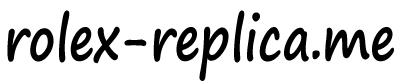

Oyster Perpetual Gmt-Master II Ref.116710BLNR born in 2013

Over the years, producing the red part of the two-tone ceramic bezel has always been technically impossible. After years of research and improvement, Rolex used its exclusive technology to make the world’s first two-color Cerachrom bezel in 2013, using blue and black.

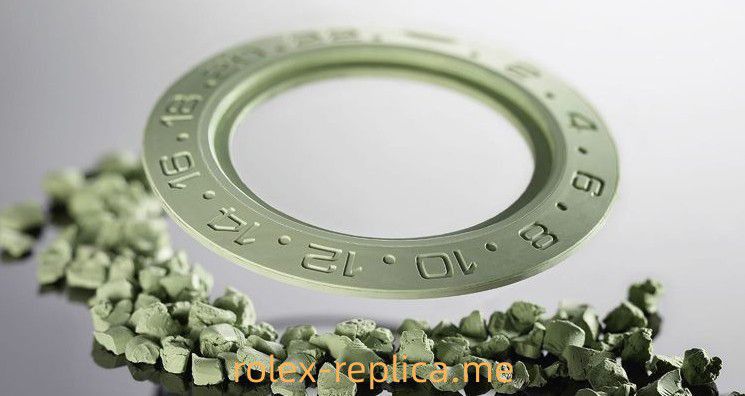

Entering 2014, the brand also produces a red and blue two-color Cerachrom bezel and adheres to the same strict quality standards as other rolex fake watch components. Rolex develops the necessary expertise, processes, and high-tech equipment in-house.

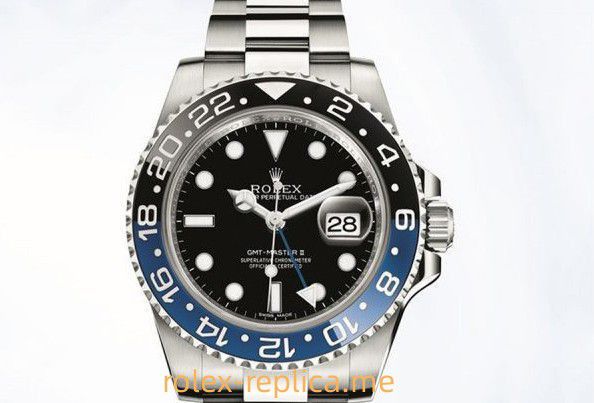

Rolex ceramic materials

Red and blue two-color CERACHROM bezel

Its manufacturing process limits the available shades of ceramic. Generally speaking, the color is formed from mineral pigments, which must withstand high-temperature firing. High-temperature firing makes the ceramic dense and gives it a unique hardness. Swiss replica watches.

However, red does not have stable mineral pigments, making it challenging to form Cerachrom components. Nonetheless, Rolex used a secret process to produce red ceramic initially. However, for the brand, this innovative technology is only half of the achievement. To be more precise, the meaningful red and blue two-color Cerachrom word circle has yet to be completed.

Rolex red and blue two-color Cerachrom bezel

Faced with the remaining challenges, Rolex engineers finally found a solution. This ingenious process involves adding innovative coloring to produce standard Cerachrom bezels. This way, half of the red ceramic word circle can turn blue. To form this color, the part of the circle representing nighttime (6 p.m. to 6 a.m.) must be immersed in a specific compound solution.

Once the solution is added, the ceramic is sintered at more than 1,600 degrees Celsius, where it becomes strong and the desired color is obtained. During this firing process, the ceramic becomes denser, and the added compounds react with the essential elements of the red Cerachrom bezel to create the final azure hue.

Rolex red and blue two-color Cerachrom bezel

This method seems simple, but many technical obstacles must be overcome before proceeding:

- The original compound solution that turns red into blue is prepared.

- The appropriate amount of solution is evenly added.

- The two color areas must be in sharp contrast and have clear boundaries.

Accurate; the next step is determining the actual sintering time and temperature to avoid deformation of the entire component. Each of the above factors is critical to the process’s success and the final product’s quality.

Pioneer tradition

Pioneering and innovation is Rolex’s fine tradition. At the beginning of the 20th century, only large marine chronometers could accurately measure time. In 1914, Rolex became the first watch brand to be awarded the “Class A” chronometer certification by the famous British Kew Observatory.

Since then, Rolex has applied for more than 400 patents and is committed to expanding into various fields of watchmaking. It has continued to evolve to create the classic watch it is today.

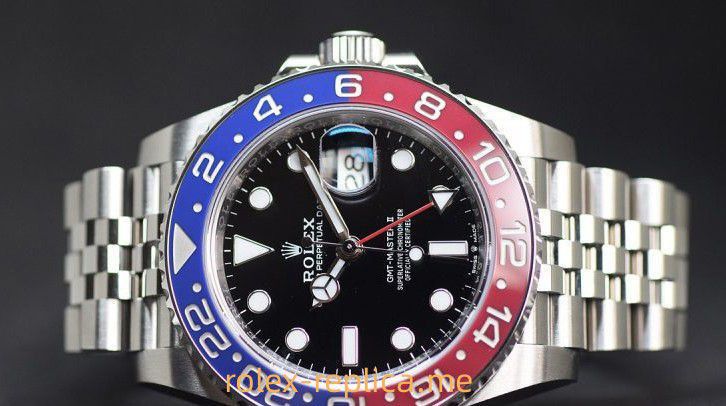

Oyster Perpetual GMT-Master II — 126710 BLRO Oyster steel case, cerachrom ceramic bi-directional rotating bezel, 40 mm diameter, hours, minutes, seconds, date, 24-hour second-time zone, 3285 self-winding movement, Power reserve of 70 hours, top chronometer certification, sapphire crystal glass, 100 meters waterproof, Oyster steel five-link commemorative strap.

Production process

Rolex has applied for two patents for this unique process. In addition to fully mastering the production process of the entire ceramic component, it can produce a two-color Cerachrom word ring. Its ingenious technology has solved technical obstacles that were once considered impossible.

Injection molding

Ceramic is made from a mixture of powders of different chemical compositions, with a binder added to allow the ceramic to take shape. The resulting wet clay is subjected to high-pressure treatment to create a word circle blank. The first high-temperature treatment removes the adhesive, leaving only the ceramic.

Maceration

This is crucial to turning half of the red word circle into blue. This half of the word circle will be injected with a chemical solution, and the process must be meticulous to allow the word circle to absorb the solution. The compound formula must also balance the concentration and weight of the solution. During the sintering stage, two colors appear.

Sintering

The lettering is then sintered at 1,600 degrees Celsius. This high-temperature treatment determines the final hardness and strength of the ceramic. The word circle will shrink by about 25% during this process, and the two colors will also be revealed.

Precision Machining

The inner and outer edges of the word ring are cut with diamond tools to achieve the precise shape and size required for the mechanical assembly process, and the appearance is modified to perfection. The sintered ceramic is so complex that only diamond tools can cut the bezel.

Progressive scale

The surface of the word ring or outer ring is filled with a thin layer of platinum using PVD (Physical Vapor Deposition) coating technology. This precious metal coating is approximately one micron thick and covers the engraved numbers and graduated scales.

Polish

Diamond polishing removes the precious metal from the surface of the outer ring, while the coating on the numbers and graduated scales remains and is visible. This process also increases the luster of the Cerachrom bezel.

Model: m126710blro-0002

Brand: Rolex

Case Color: Silver-tone

Case Size: 40mm

Series: Gmt Master Ii

Case Thickness: 15mm

Gender: Men’s